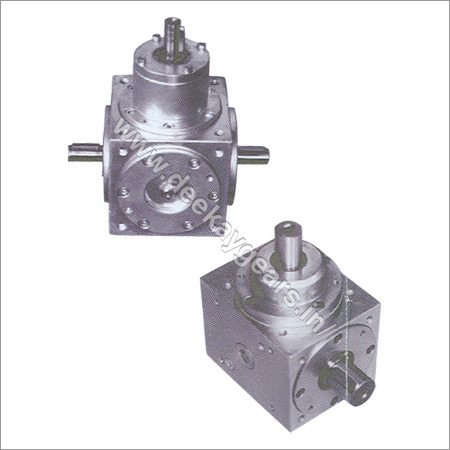

Bevel Helical Gearbox

Bevel Helical Gearbox Specification

- Gear Type

- Bevel Helical Gearbox

- Material

- Cast Iron / Alloy Steel

- Processing Type

- Precision Machined

- Gear Tooth Profile

- Helical and Bevel

- Gearing Arrangement

- Bevel/Helical

- Output Torque

- Up to 50000 Nm

- Rated Power

- 0.25 kW to 500 kW

- Input Speed

- Up to 1800 rpm

- Output Speed

- 6 rpm to 350 rpm

- Voltage

- 380V / 415V

- Efficiency

- Up to 96%

Bevel Helical Gearbox Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 6-8 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9000:2001 Certified Company

About Bevel Helical Gearbox

To meet the diversified requirements of our prestigious clients, we are engaged in offering Helical Gearbox that is available in a wide variety of specifications as per the exact requirements of clients. It is manufactured by procuring optimum grade of raw material from a highly renowned and trustworthy vendor with the help of latest tools and technology. Additionally, the offered Helical Gearbox is broadly used for heavy-duty works in steel industry, automobile industry, engineering industry and other related industry.

Features:

-

Sturdy construction

-

Highly durable

-

Smooth-finish standards

-

High tensile strength

Product Details

|

Voltage |

220V |

|

Type |

Helical |

|

Orientation |

Horizontal,Vertical |

|

Mounting |

Foot,Flange |

|

Brand |

Dee-Kay Gears |

|

Frequency |

50 Hz |

Versatile Mounting Options

Choose from foot-mounted or flange-mounted configurations to suit your installation preferences. These mounting styles allow the gearbox to be securely fixed to a wide range of machinery, providing stable operation and adaptability in various industrial environments.

Robust Construction for Longevity

Manufactured from cast iron or alloy steel with a rigid, ribbed housing, the gearbox offers excellent durability and heat dissipation. Precision machining ensures tight tolerances, prolonging service life and reducing maintenance needs, even in demanding conditions.

Efficient and Quiet Performance

With efficiency ratings up to 96% and adherence to low noise levels as per ISO standards, this gearbox delivers optimal power transmission while maintaining a quieter workplace. Oil splash lubrication further contributes to its reliable, low-noise operation.

FAQs of Bevel Helical Gearbox:

Q: How does the oil splash lubrication system benefit the Bevel Helical Gearbox?

A: The oil splash lubrication system ensures consistent and thorough lubrication of gears, minimizing friction and wear. This enhances the gearboxs reliability, reduces maintenance intervals, and maintains optimal performance even in continuous-duty applications.Q: What is the typical process for installing a foot or flange-mounted gearbox?

A: Installation begins by choosing the appropriate mounting typefoot for horizontal and flange for vertical or compact spaces. Secure the gearbox to the foundation using the provided mounting points, align with the drive connections, and fill with recommended lubricant before commissioning.Q: When should I choose a gearbox with a service factor between 1.3 and 2.0?

A: Select a gearbox with a service factor between 1.3 and 2.0 for applications with moderate to heavy loads, frequent starts and stops, or fluctuating operating conditions. The higher service factor accommodates occasional overloads, ensuring durability and long-term reliability.Q: Where can these Bevel Helical Gearboxes be sourced within India?

A: These gearboxes are available through a network of exporters, manufacturers, suppliers, and service providers across India. They can be sourced directly from certified vendors skilled in supplying high-quality industrial gear solutions.Q: What are the benefits of using EN8 or EN19 steel for gearbox shafts?

A: EN8 and EN19 steels offer superior strength, toughness, and resistance to fatigue. Using these materials for shafts ensures dependable torque transmission and extended operational life, especially in high-load and high-speed environments.Q: How does the precision machining process enhance the gearboxs performance?

A: Precision machining guarantees tight tolerances on all components, leading to smooth gear engagement, reduced vibration, and more efficient power transmission. This results in less mechanical wear, improved longevity, and consistent output quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Box Category

Cooling Tower Gearbox

Minimum Order Quantity : 1 Unit

Output Speed : 36 RPM

Output Torque : 900 Nm

Processing Type : Die Casting

Input Speed : 1440 RPM

Rated Power : 5 HP

Parallel Shaft Gearbox

Minimum Order Quantity : 1 Unit

Output Speed : 14 RPM to 186 RPM

Output Torque : Up to 750 Nm

Processing Type : Other, Precision Machined

Input Speed : Up to 1500 RPM

Rated Power : 0.18 kW to 15 kW

Planetary Gearbox

Minimum Order Quantity : 1 Unit

Output Speed : 1 RPM to 450 RPM

Output Torque : Up to 3500 Nm

Processing Type : Other, Precision Machined

Input Speed : Up to 3000 RPM

Rated Power : 0.25 kW to 150 kW

Industrial Right Angle Gearboxes

Minimum Order Quantity : 1 Unit

Output Speed : 14 RPM to 280 RPM

Output Torque : Up to 3500 Nm

Processing Type : Other, Precision Machined

Input Speed : Up to 1800 RPM

Rated Power : 0.18 kW to 90 kW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS