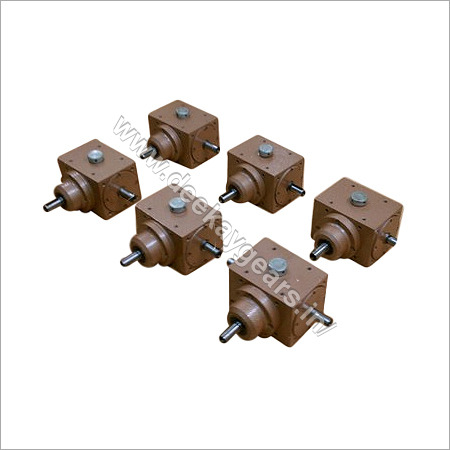

Industrial Helical Gearboxes

Industrial Helical Gearboxes Specification

- Gear Type

- Helical Gearbox

- Material

- Cast Iron

- Processing Type

- Die Casting

- Gear Tooth Profile

- Helical

- Gearing Arrangement

- Parallel

- Direction

- Both directions

- Output Torque

- Up to 18000 Nm

- Rated Power

- 0.12 kW to 160 kW

- Input Speed

- 1400 RPM

- Output Speed

- 14 RPM to 280 RPM

- Voltage

- 415 V

- Efficiency

- Up to 96%

Industrial Helical Gearboxes Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 6-8 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9000:2001 Certified Company

About Industrial Helical Gearboxes

We are engaged in offering our clients a high quality range of Industrial Helical Gearboxes that is manufactured as per the set industry norms using quality approved raw material and advanced technology. The offered gears are highly appreciated by our reputed clients for its uniqueness in features such as minimum maintenance and easy operations and are widely used in engineering and other related industries. Apart from this, we provide these Industrial Helical Gearboxes within the specific time-frame so as to cater the requirement of the reputed clients.

Features:

-

Hassle free operation

-

Simple installation

-

Longer service life

-

Excellent performance

Product Details

|

Gear Type |

Helical |

|

Features |

Industrial Gear Boxes |

|

Usage/Application |

Industrial |

|

Type |

Helical |

|

Mounting |

Vertical,Horizontal |

|

Condition |

New |

|

Orientation |

Horizontal,Vertical |

|

Product Type |

Helical |

|

Voltage |

220 |

|

Automation Grade |

Semi-Automatic |

|

Branded |

No |

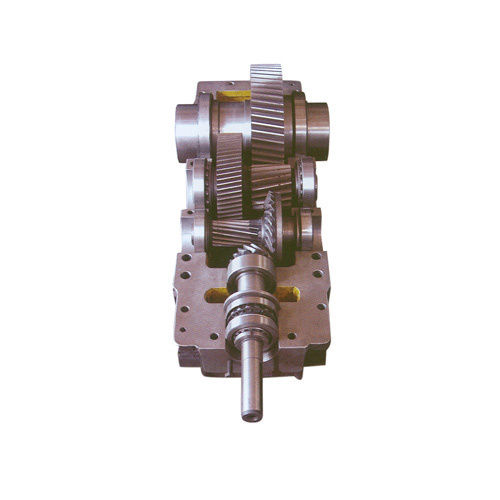

Superior Efficiency and Performance

The helical gear arrangement and oil splash lubrication work together to achieve up to 96% efficiency, minimizing energy loss and ensuring sustained, reliable power transmission. These gearboxes are engineered for low noise operation, making them ideal for sound-sensitive industrial environments.

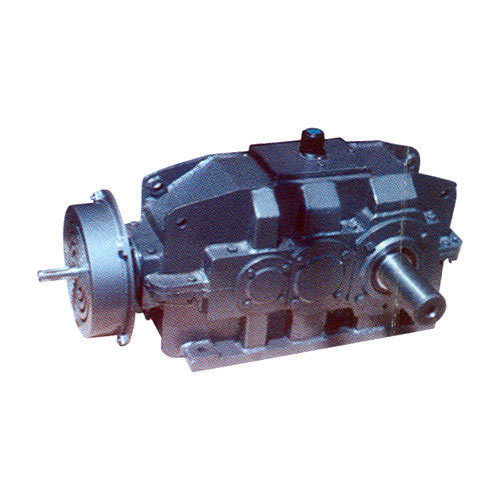

Rugged Protection and Versatile Mounting

Manufactured from die-cast cast iron and equipped with IP55 housing protection, these gearboxes endure demanding environments and resist ingress from dust and moisture. Flexible foot or flange mounting options allow broad compatibility across a range of industrial setups.

Wide Application Range

Helical gearboxes are suitable for conveyors, mixers, and various industrial machinery. The two or three-stage models, capable of bi-directional operation, provide tailored solutions for differing speed and torque needs within factories and processing plants.

FAQs of Industrial Helical Gearboxes:

Q: How does the oil splash lubrication system contribute to the gearboxs performance?

A: Oil splash lubrication ensures continuous distribution of lubricant over the gears and bearings, reducing wear and friction, which helps maintain high efficiency and extends the gearboxs operating life even under heavy loads.Q: What mounting options are available for these helical gearboxes?

A: These gearboxes support both foot and flange mounting types, providing flexibility for installation in a variety of industrial setups to best suit the arrangement and space available.Q: When should a two-stage versus a three-stage gearbox be chosen?

A: A two-stage gearbox is ideal for moderate speed and torque requirements, while a three-stage configuration is recommended for applications demanding higher torque multiplication or lower output speeds, such as heavy-duty conveyors.Q: Where can these gearboxes be used effectively?

A: Industrial Helical Gearboxes are commonly used in conveyor systems, mixers, and general-purpose machinery within factories, processing plants, and industrial facilities, particularly where robust and reliable power transmission is required.Q: What is the process for ensuring housing protection in these gearboxes?

A: The gearboxes are constructed from cast iron using a die-casting process, and the IP55-rated housing protects against dust and water ingress, ensuring durability even in challenging environmental conditions.Q: How does the gear tooth profile affect gearbox operation and noise?

A: The helical tooth profile provides smooth engagement between gears, facilitating quiet and efficient operation by minimizing vibration and reducing noise levels compared to other gear types.Q: What are the key benefits of choosing this gearbox for industrial applications?

A: Benefits include high efficiency, low operational noise, robust environmental protection, versatile mounting, suitability for bi-directional operation, and adaptability to a wide range of speed, torque, and power requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Helical Gearboxes Category

Crane Duty Helical Gear Boxes

Minimum Order Quantity : 1 Unit

Gearing Arrangement : Helical

Processing Type : Other, Precision Machined

Gear Tooth Profile : Other, Helical

Output Speed : 14280 rpm

Output Torque : Up to 25000 Nm

High Precision Helical Gearboxes

Minimum Order Quantity : 1 , , Unit

Gearing Arrangement : Other, Coaxial / Parallel Shaft

Processing Type : Other, Precision Machining

Gear Tooth Profile : Other, Helical

Output Speed : Up to 500 rpm

Output Torque : Up to 8000 Nm

Right Angle Bevel Helical Gearboxes

Minimum Order Quantity : 1 , , Unit

Gearing Arrangement : Other, Right Angle

Processing Type : Other, Precision Machined

Gear Tooth Profile : Other, Helical & Bevel

Output Speed : 14 rpm to 280 rpm

Output Torque : Up to 15000 Nm

Double Helical Gears

Minimum Order Quantity : 1 , , Unit

Gearing Arrangement : Other, Parallel shaft gearing

Processing Type : Other, Precision machining and heat treatment

Gear Tooth Profile : Other, Double helical teeth

Output Speed : Variable as per application

Output Torque : Up to 20,000 Nm (customizable)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS