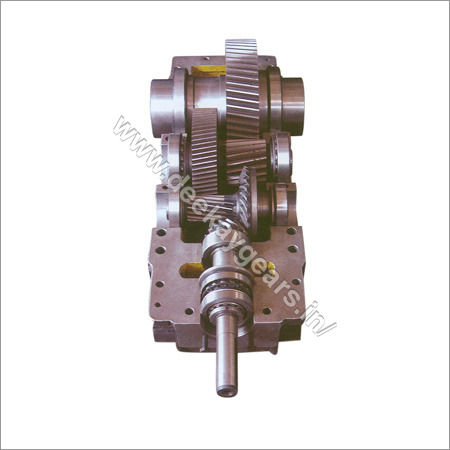

High Precision Gearboxes

High Precision Gearboxes Specification

- Gear Type

- High Precision

- Material

- Alloy Steel

- Processing Type

- Precision Machined

- Gear Tooth Profile

- Helical

- Gearing Arrangement

- Planetary

- Output Torque

- Up to 1500 Nm

- Rated Power

- Up to 20 kW

- Input Speed

- Up to 6000 rpm

- Output Speed

- Customizable as per ratio

- Efficiency

- >= 98%

High Precision Gearboxes Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 6-8 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9000:2001 Certified Company

About High Precision Gearboxes

Technical Specifications:

| Technology | Module | Od Max | Face Width Max | |

| Spur / Helical and Double Helical(With Gap) | Hobbing | 30 Module | 3000 mm | 600 mm |

| Hardened and Ground Gears | Profile Grinding | 24 Module | 2400 mm | 600 mm |

| Internal Spur | Shaping | 12 Module | 12 Module |

145 mm |

| Spiral Bevel | Kurvex Cyclo Palloid Palloid Spiromatic | 25 Module 16 Module 5 - 2 Module 6 Module 8 Module |

1000mm 600 mm 150 mm 350 mm 560 mm |

150 mm 95 mm 25 mm 60 mm 80 mm |

| Straight Bevel | Gleason H and H Klinglenberg | 10 Module 5 Module 16 Module |

500mm 200mm 250mm |

85 mm 50 mm 75 mm |

| Worm Wheel | Hobbing | 20 Module |

2000 mm | |

| Worm Shaft | Thread Milling Profile Grinding |

20 Module 20 Module |

300 mm 300mm |

500 mm 500 mm |

| Rack | Generating | 8 Module |

2000 mm Length | 150 mm |

| Sprocket | Hobbing | 3" Pitch | 2000 mm | |

| Spline Straight / Involute |

Hobbing |

20 Module |

|

600 mm |

Helical Parallel Shaft and Bevel Helical Right-Angle Drive Gear Units have been introduced to meet the requirements of todays demanding applications in the small, medium and heavy duty sector of the power transmission market with power range up to 5500 KW and ratio range up to 650/1. Modular design in concept results in minimized manufactured part and count to maximize availability of product.

Case-Hardened and Ground Helical Gears and Lapped Spiral Bevel Gears have optimized Gear Geometry to maximize strength and efficiency and to minimize noise and vibration.

Presently they are available only in fabricated housings & can be fabricated to serve as drop-in replacement to various Gearboxes of Indian and Foreign makes.

Depending upon the application variety of options can be incorporated during the development of Precision Drives Series Gearboxes:-

- Backstops

- Motors Bed-Plates

- Motor Flanges

- Cooling System

- Reinforced Bearing

- Special Shafts

- Output Bores can be connected by Shrink Disc

- Dry Well Arrangement for Vertical Reducers

- Extended Output Shaft

- Vertical Models

- Hollow Shaft Mounting

- Base Mounting

Advanced Gearbox Design

Utilizing alloy steel and cutting-edge precision machining, our helical planetary gearboxes are crafted for high performance and durability. The helical tooth profile ensures smooth and quiet operation, making the gearboxes suitable for a wide range of industrial uses that demand both efficiency and reliability.

Versatile and Robust Performance

With an adjustable output speed based on the required gear ratio, these gearboxes confidently support up to 1500 Nm of torque and 20 kW of power. Whether you operate high-speed applications or require heavy-duty torque, our gearboxes adapt to provide outstanding efficiency and minimal energy loss.

FAQs of High Precision Gearboxes:

Q: How are the high precision gearboxes processed for optimal performance?

A: These gearboxes are crafted from top-quality alloy steel and undergo advanced precision machining processes. This ensures each component meets rigorous tolerances, resulting in superior accuracy, long-term reliability, and enhanced overall gearbox performance.Q: What benefits do helical planetary gearboxes offer over other types?

A: Helical planetary gearboxes offer smoother and quieter operation due to the angled gear teeth, as well as high efficiency (98%). Their compact design allows for high torque transmission and improved load distribution, making them ideal for applications that require precision and durability.Q: When should I choose a high precision gearbox with customizable output speed?

A: You should select a customizable output speed gearbox when your application demands specific speed and torque characteristics. This allows you to tailor the systems performance for optimal results across various industrial processes and machinery.Q: Where can these gearboxes be applied for maximum benefit?

A: These high precision gearboxes are well-suited for automation equipment, robotics, machine tools, packaging machinery, and other demanding industrial systems where efficiency, reliability, and accuracy are paramount.Q: What is the typical usage process for these planetary gearboxes?

A: Install the gearbox as per the applications alignment and fitting requirements. Regularly inspect and maintain lubrication to sustain the efficiency and longevity of the gearbox. Consult technical support for guidance on integration into specific drive systems.Q: How does high efficiency in these gearboxes benefit industrial applications?

A: With an efficiency of 98% or higher, these gearboxes significantly reduce energy losses and operational costs. The efficient transmission improves total system output, leading to greater productivity and consistent performance in your machinery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS