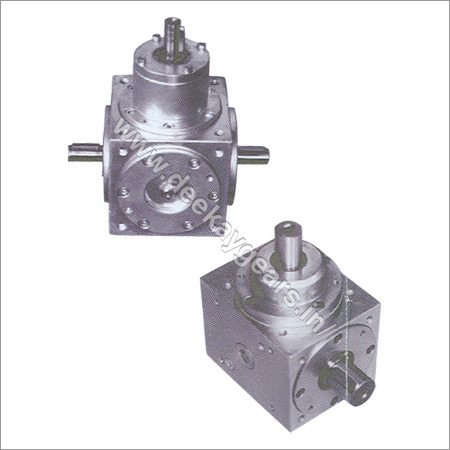

Parallel Shaft Gearbox

Parallel Shaft Gearbox Specification

- Gear Type

- Helical

- Material

- Cast Iron

- Processing Type

- Precision Machined

- Gear Tooth Profile

- Helical

- Gearing Arrangement

- Parallel Shaft

- Output Torque

- Up to 750 Nm

- Rated Power

- 0.18 kW to 15 kW

- Input Speed

- Up to 1500 RPM

- Output Speed

- 14 RPM to 186 RPM

- Voltage

- 415V AC

- Efficiency

- Up to 96%

Parallel Shaft Gearbox Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 6-8 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9000:2001 Certified Company

About Parallel Shaft Gearbox

Further Details:

Helical Parallel Shaft and Bevel Helical Right Angle Drive Gear Units have been introduced to meet the requirements of todays demanding applications in the small medium and heavy duty sector of the power transmission market with power range up to 5500 KW and ratio range up to 650/1. Modular design in concept results in minimized manufactured part and count to maximize availability of product.

Case Hardened and Ground Helical Gears and Lapped Spiral Bevel Gears have optimized Gear Geometry to maximize strength and efficiency and to minimize noise and vibration

Presently they are available only in fabricated housings and can be fabricated to serve as drop in replacement to various Gearboxes of Indian and Foreign makes.

Depending upon the application variety of options can be incorporated during the development of Precision Drives Series Gearboxes

- Backstops

- Motor Bed Plates

- Motor Flanges

- Cooling System

- Lubrication System

- Reinforces Bearing

- Special Shafts

- Output Bores can be connected by Shrink Disc

- Dry Well Arrangement for Vertical Reducers

- Extended Output Shaft

- Vertical Models

- Hollow Shaft Mounting

- Base Mounting.

Product Details

|

Gear Type |

Helical |

|

Features |

Parallel Shaft Gearboxes |

|

Usage/Application |

Industrial |

|

Mounting |

Horizontal |

|

Orientation |

Horizontal,Vertical |

|

Product Type |

Helical |

|

Automation Grade |

Semi-Automatic |

|

Branded |

No |

Precision Engineering for Reliable Operation

Our Parallel Shaft Gearbox stands out due to its precision-machined construction, delivering dependable and consistent performance. The use of cast iron ensures structural durability, while the helical gear tooth profile minimizes noise and vibration, making it ideal for demanding industrial applications where reliability is paramount.

Flexible Power and Speed Solutions

Engineered to cover a wide spectrum of demands, this gearbox accommodates input speeds of up to 1500 RPM, with output speeds ranging from 14 to 186 RPM. With power ratings from 0.18 kW to 15 kW and torque up to 750 Nm, it is versatile enough for diverse usage scenarios, ensuring adaptability across various sectors.

FAQs of Parallel Shaft Gearbox:

Q: How is the Parallel Shaft Gearbox processed and what benefits does precision machining offer?

A: The gearbox is manufactured using precision machining techniques, which guarantee accurate gear meshing and tight tolerances. This leads to higher efficiency, reduced operational noise, and longer lifespan compared to standard processing methods.Q: What industrial applications can benefit from the Parallel Shaft Gearbox?

A: This gearbox is suitable for machinery requiring reliable torque and controlled speed, such as conveyors, mixers, and material handling equipment. Its robust cast iron construction and helical gear design make it ideal for heavy-duty and continuous operations in manufacturing plants.Q: When should I use a helical gear tooth profile in a gearbox?

A: You should use a helical gear tooth profile when you require smooth and quiet operation, along with greater load-carrying capacity. Helical gears provide better torque transmission and higher efficiency, making them preferable in demanding industrial environments.Q: Where are your Parallel Shaft Gearboxes manufactured and supplied from?

A: We manufacture, export, and supply these gearboxes from our facilities in India. Our products reach clients domestically as well as internationally, ensuring global standards in performance and quality.Q: What is the process of selecting the right Parallel Shaft Gearbox for my application?

A: Selecting the suitable gearbox involves evaluating your power requirements, input speed, output speed, and torque demands. Our technical support team assists clients by recommending the appropriate model based on specific operational needs and application details.Q: How does the parallel shaft gearing arrangement improve gearbox performance?

A: The parallel shaft design optimizes power transfer with minimized losses, promoting higher efficiencyup to 96%. This configuration facilitates straightforward installation and alignment in machinery, making maintenance simpler and downtime minimal.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Box Category

Cooling Tower Gearbox

Minimum Order Quantity : 1 Unit

Processing Type : Die Casting

Voltage : 415 V

Input Speed : 1440 RPM

Gear Tooth Profile : Other, Helical

Rated Power : 5 HP

Planetary Gearbox

Minimum Order Quantity : 1 Unit

Processing Type : Other, Precision Machined

Voltage : 220V / 380V / 415V

Input Speed : Up to 3000 RPM

Gear Tooth Profile : Other, Helical or Spur

Rated Power : 0.25 kW to 150 kW

Bevel Helical Gearbox

Minimum Order Quantity : 1 Unit

Processing Type : Other, Precision Machined

Voltage : 380V / 415V

Input Speed : Up to 1800 rpm

Gear Tooth Profile : Other, Helical and Bevel

Rated Power : 0.25 kW to 500 kW

Industrial Right Angle Gearboxes

Minimum Order Quantity : 1 Unit

Processing Type : Other, Precision Machined

Voltage : 415 V

Input Speed : Up to 1800 RPM

Gear Tooth Profile : Other, Spur / Helical

Rated Power : 0.18 kW to 90 kW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free