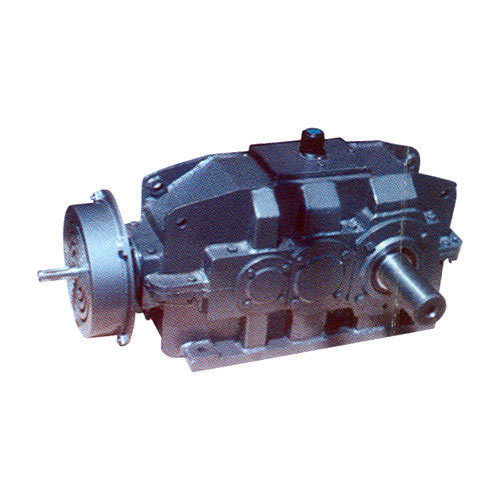

Helical Gear Box

Helical Gear Box Specification

- Gear Type

- Helical

- Material

- Cast Iron

- Processing Type

- Precision Machined

- Gear Tooth Profile

- Helical

- Gearing Arrangement

- Coaxial / Parallel Shaft

- Output Torque

- Up to 12,000 Nm

- Rated Power

- Up to 350 kW

- Input Speed

- Up to 1800 rpm

- Output Speed

- 5 to 600 rpm

- Voltage

- 415 V

- Efficiency

- 95% to 98%

Helical Gear Box Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 6-8 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9000:2001 Certified Company

About Helical Gear Box

Further Information:

Helical Parallel Shaft and Bevel Helical Right Angle Drive Gear Units have been introduced to meet the requirements of todays demanding applications in the small medium and heavy duty sector of the power transmission market with power range up to 5500 KW and ratio range up to 650/1. Modular design in concept results in minimized manufactured part and count to maximize availability of product.

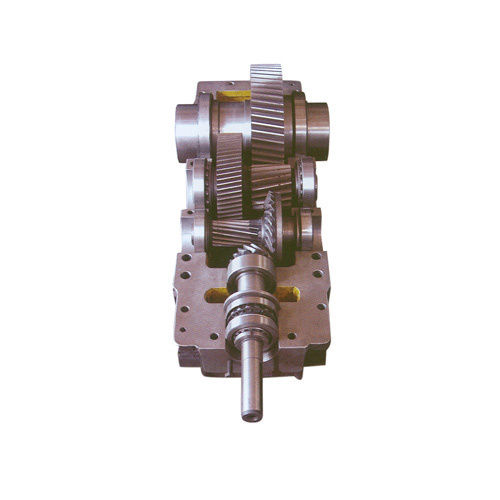

Case Hardened and Ground Helical Gears and Lapped Spiral Bevel Gears have optimized Gear Geometry to maximize strength and efficiency and to minimize noise and vibration

Presently they are available only in fabricated housings and can be fabricated to serve as drop in replacement to various Gearboxes of Indian and Foreign makes.

Depending upon the application variety of options can be incorporated during the development of Precision Drives Series Gearboxes

- Backstops

- Motor Bed Plates

- Motor Flanges

- Cooling System

- Lubrication System

- Reinforces Bearing

- Special Shafts

- Output Bores can be connected by Shrink Disc

- Dry Well Arrangement for Vertical Reducers

- Extended Output Shaft

- Vertical Models

- Hollow Shaft Mounting

- Base Mounting

Product Details

|

Brand |

Dee-Kay Gears |

|

Type |

Helical |

|

Orientation |

Vertical,Horizontal |

|

Power |

1100 |

|

Mounting |

Flange |

|

Condition |

New |

Superior Performance and Efficiency

The helical gear box offers industry-leading efficiency between 95% and 98%, ensuring minimal energy loss during operation. Built from high-quality cast iron and precisely machined, it is designed to handle demanding industrial workloads while maintaining optimal performance standards.

Flexible Applications in Diverse Industries

Thanks to its coaxial and parallel shaft gearing arrangements, variable output speed (5600 rpm), and high output torque capacity, this gear box is suited for a broad range of sectors, including manufacturing, power plants, mining, and material handling. Its versatility makes it an essential component for various industrial processes.

FAQs of Helical Gear Box:

Q: How does the helical gear box ensure high efficiency in industrial operations?

A: The helical gear box features a helical tooth profile, which promotes smooth and gradual engagement of gears, reducing vibration and energy loss. Combined with precision machining and robust cast iron construction, this design achieves operating efficiencies between 95% and 98%, minimizing power loss and enhancing reliability in demanding environments.Q: What are the primary benefits of using a coaxial or parallel shaft helical gear box?

A: Coaxial and parallel shaft arrangements provide flexible mounting options and simplified power transmission alignments. This design allows for optimal placement within systems, reduced installation complexity, and improved load distribution, which collectively enhance machine performance and longevity.Q: Where is the helical gear box typically used in industry?

A: These gear boxes are widely employed in industries such as cement, steel, mining, power generation, and materials transport. Their ability to handle torque up to 12,000 Nm and power up to 350 kW makes them ideal for applications requiring reliable, heavy-duty transmission solutions.Q: What processes are used to manufacture the helical gear box?

A: The gear boxes are manufactured through precision machining, ensuring tight tolerances and superior surface finish. High-strength cast iron is used for structural robustness, while meticulous quality checks guarantee that every gear and component meets international standards for performance and durability.Q: How should the helical gear box be maintained for optimal usage?

A: Regular maintenance should include timely lubrication, periodic inspection for wear on gear teeth and shafts, and verification of alignment and tightness of mounting bolts. Following the manufacturers maintenance schedule will maximize operational life and maintain high efficiency.Q: When should a helical gear box be chosen over other gear types?

A: A helical gear box is preferred when quiet operation, high efficiency, and the ability to handle significant torque loads are priorities. Its design makes it suitable for continuous or heavy-duty applications where durability and smooth performance are critical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Helical Gearboxes Category

Right Angle Bevel Helical Gearboxes

Minimum Order Quantity : 1 , , Unit

Gear Tooth Profile : Other, Helical & Bevel

Direction : Bidirectional

Rated Power : Up to 160 kW

Efficiency : Up to 96%

Input Speed : 1500 rpm (Nominal)

Crane Duty Helical Gear Boxes

Minimum Order Quantity : 1 Unit

Gear Tooth Profile : Other, Helical

Direction : Bidirectional

Rated Power : Up to 160 kW

Efficiency : Up to 98%

Input Speed : 1440 rpm

High Precision Helical Gearboxes

Minimum Order Quantity : 1 , , Unit

Gear Tooth Profile : Other, Helical

Direction : Bidirectional

Rated Power : Up to 160 kW

Efficiency : Up to 98%

Input Speed : Up to 4000 rpm

Double Helical Gears

Minimum Order Quantity : 1 , , Unit

Gear Tooth Profile : Other, Double helical teeth

Direction : Bidirectional operation

Rated Power : Up to 200 kW

Efficiency : Up to 98%

Input Speed : Up to 2000 rpm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS