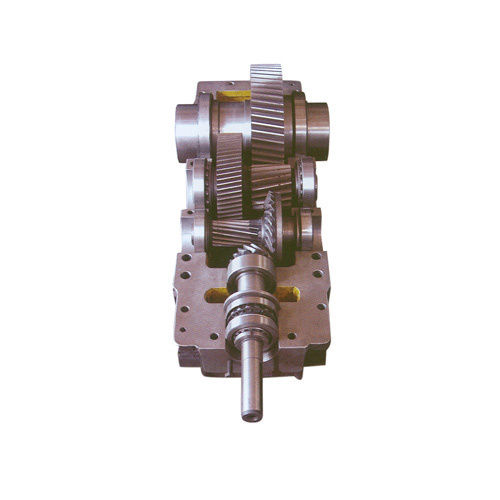

High Precision Helical Gearboxes

High Precision Helical Gearboxes Specification

- Gear Type

- Helical

- Material

- Alloy Steel

- Processing Type

- Precision Machining

- Gear Tooth Profile

- Helical

- Gearing Arrangement

- Coaxial / Parallel Shaft

- Direction

- Bidirectional

- Output Torque

- Up to 8000 Nm

- Rated Power

- Up to 160 kW

- Input Speed

- Up to 4000 rpm

- Output Speed

- Up to 500 rpm

- Voltage

- 380V / 415V

- Efficiency

- Up to 98%

High Precision Helical Gearboxes Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 6-8 Week

About High Precision Helical Gearboxes

Versatile Performance for Robust Applications

High Precision Helical Gearboxes are specifically designed for both general and demanding industrial uses such as material handling, conveyors, and mixers. Their bidirectional operation and high efficiency make them ideal for continuous use in automation and processing environments. The main advantage lies in their long service life and silent operation, supported by precision-machined helical gears. Direction of use is flexiblesimply install using foot or flange mounts and achieve steadfast operation in either direction as required.

Trade Terms, Valuation, and Market Coverage

Our High Precision Helical Gearboxes are handed over at prominent FOB ports of India, ensuring prompt international dispatch. Flexible payment terms accommodate a wide range of valuation needs to fit your asking price and budget. These gearboxes serve the main domestic market across India with steadfast reliability, offering exporters, manufacturers, suppliers, and service providers a trusted solution for large-scale and bespoke applications.

FAQs of High Precision Helical Gearboxes:

Q: How do High Precision Helical Gearboxes enhance industrial automation systems?

A: With up to 98% efficiency and low noise, these gearboxes maximize productivity and create a stable, quiet environment in industrial automation, supporting complex machinery with reliable torque and power.Q: What mounting options are available for these helical gearboxes?

A: Both foot-mounted and flange-mounted configurations are offered, allowing for versatile installation according to your setup and space requirements in various applications.Q: Where are these gearboxes primarily used?

A: They are widely utilized in industries such as material handling, conveyors, crushers, mixers, and other automation-driven environments needing robust and precise motion control.Q: What is the advantage of using oil bath or forced lubrication in the gearbox?

A: Oil bath and forced lubrication systems ensure optimal gear performance by minimizing wear and maximizing service life, supporting continuous heavy-duty use with reduced maintenance.Q: When should a gearbox with a corrosion-resistant coating be chosen?

A: Select corrosion-resistant coated gearboxes for operations in harsh, high-humidity, or chemically aggressive environments to prevent degradation and ensure years of reliable service.Q: What is the process for ordering and handing over these gearboxes?

A: After confirming your order and payment terms, units are prepared and handed over promptly at a major Indian FOB port for smooth domestic or international delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Helical Gearboxes Category

Industrial Helical Gearboxes

Minimum Order Quantity : 1 Unit

Output Speed : 14 RPM to 280 RPM

Material : Other, Cast Iron

Gear Tooth Profile : Other, Helical

Rated Power : 0.12 kW to 160 kW

Processing Type : Die Casting

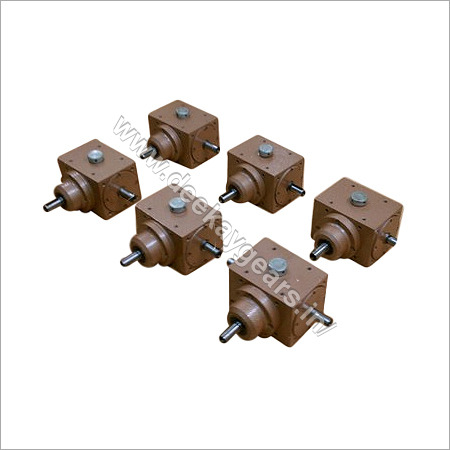

Helical Gear Box

Minimum Order Quantity : 1 Unit

Output Speed : 5 to 600 rpm

Material : Other, Cast Iron

Gear Tooth Profile : Other, Helical

Rated Power : Up to 350 kW

Processing Type : Other, Precision Machined

Right Angle Bevel Helical Gearboxes

Minimum Order Quantity : 1 , , Unit

Output Speed : 14 rpm to 280 rpm

Material : Other, Alloy Steel / Cast Iron

Gear Tooth Profile : Other, Helical & Bevel

Rated Power : Up to 160 kW

Processing Type : Other, Precision Machined

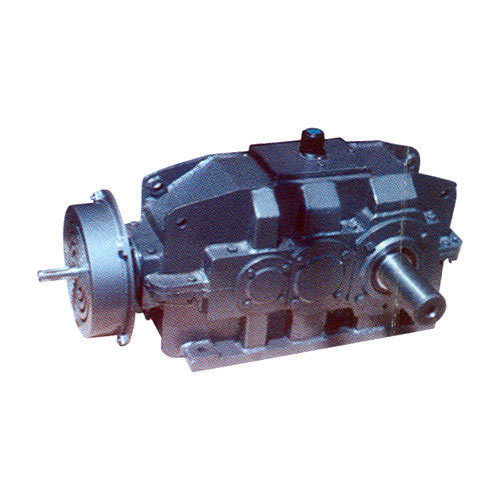

Crane Duty Helical Gear Boxes

Minimum Order Quantity : 1 Unit

Output Speed : 14280 rpm

Material : Other, Cast Iron (Body), Hardened Steel (Gears)

Gear Tooth Profile : Other, Helical

Rated Power : Up to 160 kW

Processing Type : Other, Precision Machined

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS