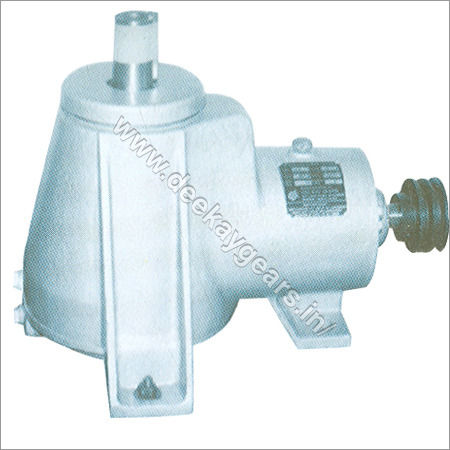

Right Angle Fan Drives

Right Angle Fan Drives Specification

- Gear Type

- Bevel Gear

- Material

- Cast Iron / Steel

- Processing Type

- Precision Machined

- Gear Tooth Profile

- Helical / Spur

- Gearing Arrangement

- Right Angle Bevel

- Direction

- Reversible

- Output Torque

- 250 Nm to 2000 Nm

- Rated Power

- Up to 150 kW

- Input Speed

- Up to 1800 rpm

- Output Speed

- 300 rpm to 900 rpm

- Voltage

- 380V / 415V

- Efficiency

- Up to 96%

Right Angle Fan Drives Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 6-8 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9000:2001 Certified Company

About Right Angle Fan Drives

Additional Specifications:

Dee - Kay Gears CT Series Right Angle Gear Drives for Cooling Tower Gearboxesare designed to serve as drop in replacements for the Marley and Paharpur make Cooling Towers. The Unique feature is that these Cooling TowerGearboxes are in single piece construction for proper bearing alignment and toughness. They feature high quality, Case - hardened and Lapped alloy steel Generated Spiral Bevel Gear in single stage and Hardened and Ground Helical Gear in the double stage. Available is 8 Sizes, are manufactured to utmost quality and rigidity considering the torture in terms of usage and working condition.

Product Details

|

Maximum Input Speed |

Standard |

|

Brand |

Dee-Kay |

|

Size |

Standard |

|

Material |

Cooling Tower Gear Drives |

|

L One Stages |

Standard |

Engineered for Heavy-Duty Performance

Constructed from high-grade cast iron or steel and precisely machined, these right angle fan drives excel in heavy industrial fan and blower applications. The combination of helical or spur gear profiles with a reliable right angle bevel arrangement ensures long service life and superior efficiency.

Optimized Cooling and Protection

Equipped with fan cooled housings and a totally enclosed design, these drives ensure optimal thermal management and protect internal components from contaminants. Oil splash lubrication further enhances reliability and minimizes maintenance over time.

Versatile and Efficient Power Transfer

With output torque ranging from 250 Nm to 2000 Nm and rated power up to 150 kW, these drives accommodate a variety of industrial requirements. Reversible operation, multiple voltage compatibility, and up to 96% efficiency deliver versatile, dependable performance.

FAQs of Right Angle Fan Drives:

Q: How does the right angle gearing arrangement improve efficiency and reliability?

A: The right angle bevel gear arrangement allows for smooth torque transmission while changing the direction of power flow. When combined with helical or spur gear profiles and precision machining, this setup delivers high efficiencyup to 96%and reduces wear, resulting in superior reliability for heavy-duty applications.Q: What industrial applications are these fan drives suitable for?

A: These fan drives are specifically designed for heavy industrial fans and blowers, commonly found in sectors such as power generation, steel mills, cement plants, and chemical processing facilities where robust, reliable, and efficient operation is crucial.Q: When should oil splash lubrication be checked or changed?

A: Regular maintenance checks should be performed as recommended in the manufacturers manual. For continuous heavy-duty use, it is advisable to inspect oil levels periodically and change the lubricant according to operational hours or at least every six months to maintain optimal performance and prolong service life.Q: Where can these right angle fan drives be installed?

A: Thanks to versatile mounting optionseither foot or flange mountedthese drives can be installed in a wide range of fan and blower systems in industrial environments, ensuring flexibility in both new installations and retrofits.Q: What is the benefit of the corrosion resistant paint coating?

A: The corrosion resistant paint coating provides long-term protection against harsh environmental conditions, preventing rust and degradation. This extends the service life of the drives, especially in demanding industrial settings where exposure to dust, moisture, or chemicals is common.Q: How does the totally enclosed housing enhance drive performance?

A: A totally enclosed housing safeguards internal components from dust, debris, and moisture ingress, ensuring consistent performance and reducing unplanned downtime due to contamination-related wear or failures.Q: What processes are involved in ensuring precision and durability of these drives?

A: The drives are manufactured using advanced precision machining techniques and high-quality materials (cast iron or steel). Every component is engineered and tested to meet rigorous industrial standards, resulting in dependable operation and long service life, even in the most challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Drives Category

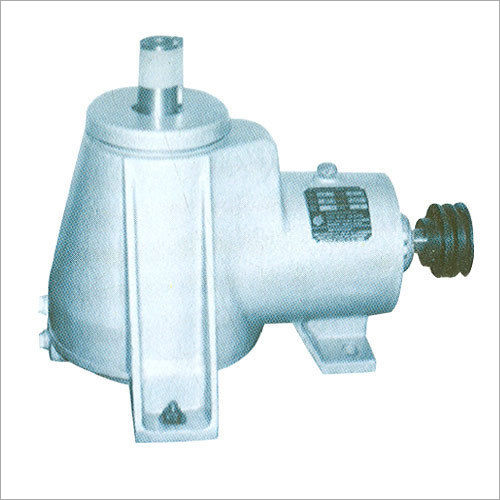

Right Angle Gear Drives

Minimum Order Quantity : 1 Unit

Output Torque : Up to 2500 Nm

Voltage : 380V / 415V

Gear Tooth Profile : Other, Spur / Helical

Gear Type : Other, Bevel / Spiral Bevel

Processing Type : Other, Precision Machined

Right Angle Gear Drives

Minimum Order Quantity : 1 Unit

Output Torque : Up to 250 Nm

Voltage : Not applicable (mechanical unit)

Gear Tooth Profile : Other, Spur / Bevel

Gear Type : Other, Bevel Gear

Processing Type : Other, Precision Machined

Cooling Tower Gear Drives

Minimum Order Quantity : 1 Unit

Output Torque : 1000 Nm 60000 Nm

Voltage : 415 V

Gear Tooth Profile : Other, Helical

Gear Type : Other, Helical Gear Drive

Processing Type : Other, Precision Machined

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free