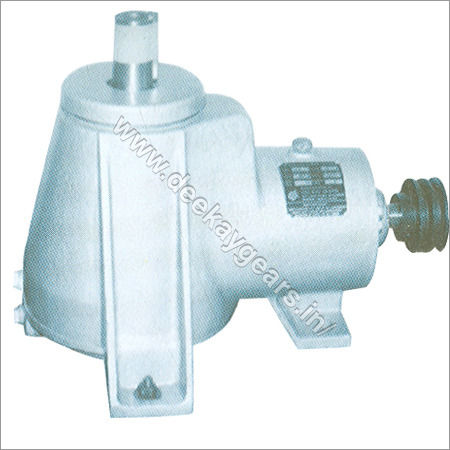

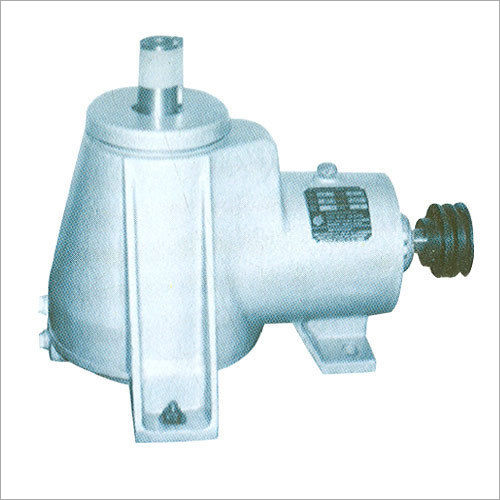

Right Angle Gear Drives

Right Angle Gear Drives Specification

- Gear Type

- Bevel / Spiral Bevel

- Material

- High Grade Alloy Steel

- Processing Type

- Precision Machined

- Gear Tooth Profile

- Spur / Helical

- Gearing Arrangement

- Right Angle

- Output Torque

- Up to 2500 Nm

- Rated Power

- Up to 30 kW

- Input Speed

- Up to 1500 rpm

- Output Speed

- Up to 1500 rpm

- Voltage

- 380V / 415V

- Efficiency

- Up to 98%

Right Angle Gear Drives Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 6-8 Week

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9000:2001 Certified Company

About Right Angle Gear Drives

Additional Details:

Dee-Kay Gears RAD Right-Angle Gear Drives provides positive power transmission from horizontal prime movers to vertical pump shafts. It offers economy, efficiency, space saving and the ability to function well under varying climate conditions. Dee-Kay Gears RAD Right-Angle Gear Drives are used in a variety of applications such as irrigation, municipal water supply & sewage disposal fire protection, flood protection, cooling towers, wind towers and marine service. A variety of models are available to meet specific requirement of high and low speed prime movers and pumps.

Product Details

|

Weight |

Standard |

|

Brand |

Dee-Kay |

|

Size |

Standard |

|

Material |

Right Angle Gear Drives |

|

L One Stages |

Standard |

|

Maximum Input Speed |

Standard |

Exceptional Durability with Precision Engineering

Built from high-grade alloy steel and precisely machined, our right angle gear drives ensure maximum durability even under demanding industrial situations. The advanced gear tooth profilesincluding spur, helical, bevel, and spiral bevelsupport efficient power transmission and reliable long-term operation.

Versatile Applications Across Industries

With a robust output torque of up to 2500 Nm and power capabilities up to 30 kW, our right angle gear drives are suitable for a wide range of applications. Whether used in conveyor systems, mixers, or heavy machinery, these drives deliver consistent performance at speeds up to 1500 rpm.

High Efficiency and Energy Savings

Optimized for efficiency rates as high as 98%, our gear drives minimize energy losses and deliver cost-effective operation. Users benefit from reduced maintenance needs and extended service life, enhancing overall productivity for industrial operations.

FAQs of Right Angle Gear Drives:

Q: How are the right angle gear drives manufactured to ensure precision and durability?

A: These gear drives are manufactured using high grade alloy steel and undergo precision machining processes. This approach ensures tight tolerances, optimal fit, and long-lasting durability for demanding industrial environments.Q: What types of gear profiles are available in your right angle gear drives?

A: Our gear drives incorporate both spur and helical gear tooth profiles, as well as bevel and spiral bevel gear types. This range provides versatile solutions tailored to different mechanical power transmission needs.Q: When should I consider using a right angle gear drive?

A: Right angle gear drives are ideal when you need to transmit power between shafts at a 90-degree angle. Their robust construction supports applications like conveyors, mixers, crushers, and heavy-duty industrial processes requiring efficient torque transfer.Q: Where are these right angle gear drives typically used?

A: Commonly, these gear drives are used in industrial settings such as manufacturing plants, conveyors, packaging machinery, and material handling equipment where space constraints and right angle power transmission are crucial.Q: What is the process for selecting the appropriate gear drive for my application?

A: Selection involves considering your required output torque (up to 2500 Nm), rated power (up to 30 kW), input/output speed (up to 1500 rpm), and voltage (380/415V). Consulting our technical support team can help match specific specifications to your application needs.Q: How does using high efficiency gear drives benefit my operation?

A: With efficiency ratings up to 98%, these gear drives reduce energy losses and operational costs. Higher efficiency also means less heat generation, improved reliability, and extended life for both the gearbox and connected machinery.Q: What kind of after-sales service and support do you provide?

A: As a manufacturer, exporter, supplier, and service provider, we offer comprehensive after-sales support, including installation guidance, maintenance services, and timely supply of spare parts for ongoing reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Drives Category

Right Angle Fan Drives

Minimum Order Quantity : 1 Unit

Input Speed : Up to 1800 rpm

Gear Tooth Profile : Other, Helical / Spur

Gearing Arrangement : Other, Right Angle Bevel

Rated Power : Up to 150 kW

Output Torque : 250 Nm to 2000 Nm

Right Angle Gear Drives

Minimum Order Quantity : 1 Unit

Input Speed : Up to 1800 RPM

Gear Tooth Profile : Other, Spur / Bevel

Gearing Arrangement : Other, Right Angle

Rated Power : Up to 5 kW

Output Torque : Up to 250 Nm

Cooling Tower Gear Drives

Minimum Order Quantity : 1 Unit

Input Speed : 1440 RPM

Gear Tooth Profile : Other, Helical

Gearing Arrangement : Other, Helical Gear

Rated Power : 10 HP 100 HP

Output Torque : 1000 Nm 60000 Nm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS